Medical waste management is about reducing risk to the environment and patients, and also to people who work at the medical facilities where the waste is generated or stored. Industrial hygiene is the term for the discipline of study and practice of managing risks to personnel; it is a rich field with academic credentials and commercial certifications. Industrial hygiene, or occupational hygiene, intersects with waste management. The functions are often done by the same individual. One of the hazards posed to workers is the generation and storage of waste.

Waste managers usually focus on the waste - its nature, how it is generated, and where it is stored. Industrial hygienists look at people first, and what their jobs entail. A job and place (worksite) analysis considers risks employees face. Threats to worker health - whether biological, chemical, or physical are identified and enumerated in an industrial hygiene analysis. Industrial hygiene activities also involve taking action to prevent or minimize exposure to hazards. See our page on safety questions.

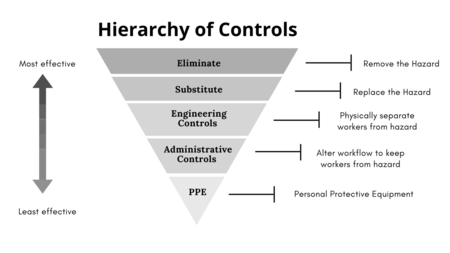

These actions take the form of controls, and the NIOSH website enumerates a hierarchy of controls. Elements include Elimination of the hazard (most preferred), Substitution, Engineering Controls, Administrative Controls, and PPE (least preferred). These elements are somewhat analogous to those in the waste management hierarchy.

These actions take the form of controls, and the NIOSH website enumerates a hierarchy of controls. Elements include Elimination of the hazard (most preferred), Substitution, Engineering Controls, Administrative Controls, and PPE (least preferred). These elements are somewhat analogous to those in the waste management hierarchy.

Threats to health in the air can include dissolved gases (e.g. chlorine, hydrogen sulfide), solid particles (dust, fibers), and liquid particles (aerosols). Biological pathogens can also travel through the air, sometimes through aerosols.

Dusts are solid particles. Many human activities generate dust, not just obvious grinding or crushing of materials. Fumes are similarly solid particles, but usually much finer, and result when a volatilized solid condenses in the air. Often the chemical form of the reformed solid is different from that of the initial solid. Fibers are solid particles in cylindrical or rope shape; asbestos is a fiber hazard.

Mists or aerosols are like dust but with liquid particles. They are likewise generated by many human activities, including human breathing, but form especially when splashing is going on. Fumes and mists often are the source of odors. The dissolved gases and aerosol particles can be chemical hazards, as can the solid particulates.

Some dust is classified as “nuisance dust” and is not considered a health threat. Inhalable dust, on the other hand, can get in the lungs. These are particles of less than 100 micrometers aerodynamic equivalent diameter (AED) that enters through the nose and or mouth. Even smaller particles (less than 10 micrometers AED) are respirable dust and an even bigger threat to health. Workers in areas with inhalable and/or respirable dust should wear masks or respirators.

The most frequent reason for OSHA citations at hospitals is inadequate Respiratory Protection.

Pathogens are the chief biological hazard to worry about and at the types of facilities we discuss on the Malsparo website. These include bacteria, viruses, and fungi that can cause acute and chronic infections by entering the body either directly or through breaks in the skin.

Biological hazards can be present at any worksite, even those outside the medical industry. Disease-causing germs can be classified as conventional pathogens (which can cause disease in healthy people), and conditional pathogens and opportunistic pathogens (which are risks for people with weak immune systems.) If there is an inordinate danger of infection, workers should wear appropriate protective equipment. Insect bites and animal dropping are less common biological hazards for people working indoors.

Blood and other bodily fluids are of special concern because they fall under explicitly OSHA rules.

Modern medicine uses radiation, people who work at medical facilities are at risk. Equipment normally has shielding to prevent dangerous radiation from affecting employees. Medical waste can be radioactive, too.

These include noise, vibration, and temperature.

Threats to bodily health from physical position, environment, or movement. Ergonomic hazards include excessive vibration, eye strain, repetitive motion, noise, and heavy lifting. Improperly designed tools or work areas also can be ergonomic hazards. Evaluating working conditions from an ergonomics standpoint involves looking at the total physiological and psychological demands of the job on the worker.

You need to install signs alerting employees to hazards. Indeed, failure to properly communicate hazards to employees is the second most frequent source of OSHA violations. The Hazard Communication Standard is now accepted in most jurisdictions, and if you follow it, you will be all right with US-based regulators. The standard calls for a pictogram, a single signal word (e.g. "Danger"), and a hazard statement.

In industrial operations, cleaning means removal of unwanted dirt or debris. There is an industry dedicated to it, and many vendors sell cleaning products (usually detergents, but sometimes with antimicrobial disinfactants.) For medical facilities, cleaning must encompass removal of biological materials. Both the building and equipment in it can be cleaned for safe handling and/or further decontamination.

We recommend employers provide PPE to employees who work near hazards. Some places have locker rooms and showers. Medical practitioners have procedures and standards for washing hands. Even employees who do not work with patients should have options for hand washing, if only to protect themselves.